What’s New

The Ultimate Guide to Machine Vise – Here Is All You Need To Know

Have you ever wondered what the best machine vice is, or which one to buy? There are many different mechanical machine vises, and they all have technical names to match. The truth is that most vices work great. Your needs will dictate what kind of machine vice you end up buying.

If you are looking for a comprehensive guide on using a machine vice or have never used one before and want to know what it's all about, this is the go-to source for all your answers.

What Are Machine Vises?

Machine vises are a particular type of plumbing tool that is used to grip pipes securely. Their primary purpose is to provide extra support for the lines, so they don't move while you're working on them. They also help hold the pipes at an angle so they can be easily worked on.

Machine vises are the world's most valuable and most underrated tool. If you don't have one, you're missing a lot of freedom in the workshop.

They come in various styles and capabilities, but what they all have in common is their ability to hold onto a piece of stock and swivel around an axis.

Their application is limitless: clamping down something that needs to be held still while you work on it; holding onto something that needs to be clamped down; supporting something for dimensional stability or strength; clamping down something that needs to be turned or moved; holding onto something that needs to be rotated. Machine vises are a big deal.

Working Mechanism

The working mechanism of machine vice is quite simple. A clamp's primary function is to apply pressure or force to hold something in place using a mechanical fastener such as a bolt or screw. Another way to distinguish a machine vice from a clamp is that in the case of a machine vice, the holding is done by its jaws and not the mechanical fastener.

Machine vises hold a workpiece at a fixed distance from the machine's spindle. They can be used for storing a workpiece during machining or clamping it in place while you drill or tap holes.

The simplest types of machine vice use two clamping jaws that are moved towards each other to grip the workpiece. A screw mechanism usually connects the jaws, and there may also be some lever or handle that raises or lowers them.

Other types of vice use pneumatic, hydraulic, or electrical actuation to move their jaws into position. Some models even have multiple sets of jaws to hold multiple parts at once. These more complex types of machines vice tend to cost more than simpler ones but can save time if you need to make repetitive modifications on several parts simultaneously.

Types of Machine Vise

1. Any-Angle Precision Angle Machine Vise

This type of vice is used in home improvement projects and woodworking. It can be used to hold materials at any angle. The jaws of the vice open up to 90 degrees and can be adjusted to any angle you want.

These vices are made from cast iron and steel, making them more durable than other vices. They are also more affordable than different types of vices, so they can be a good option if you're on a budget.

2. Ultra-Precision Vises

These vices are used for delicate work such as jewellery making or watch repairing. They feature very tight clamping forces, which means they hold objects very securely without marring or damaging them.

These vices can also be adjusted to any angle so that you can position your object exactly how you want it before securing it with one hand while working on it with the other hand.

Ultra-precision vices are often made from high-quality materials such as stainless steel, brass and aluminium because these materials do not rust or corrode like other metals would if they were exposed to water or moisture in the air over time.

3. Self-Centring Machine Vise

A self-centring machine vise is the most common type of machine vise. It has a sliding jaw that can be locked into place and a base that holds the workpiece.

The sliding jaw allows you to apply pressure to any part of the workpiece by moving it to the desired spot. This type of machine vice is perfect for holding round objects while they are being machined or drilled.

4. Cross-Slide Drill Press Milling Vise

The cross-slide drill press milling vice is similar to a self-centring machine vice but with one crucial difference: it features a cross slide that makes it easier to position your workpiece for drilling or milling operations.

This type of machine vice is ideal for holding round objects. In contrast, they are machined or drilled because you can position them precisely where you want them without worrying about them slipping out of position when you apply pressure to them with the sliding jaw.

Top 5 Advantages of Machine Vise

1. Machine Vice Is Easy To Use

Using a machine vice is very simple. All you need to do is place your workpiece in the wrong and tighten it using the lever. To release the vice, turn the lever back to its original position. The jaws of the machine vice will automatically open up and remove your workpiece.

2. Machine Vice Can Grip Different Shapes And Sizes

A machine vice doesn't limit the size or shape of your workpiece because they can easily be adjusted by adjusting their jaws and moving them closer or farther apart.

3. Machine Vice Is More Durable Than Hand Vices

The materials used for these types of vices are more robust than those used in hand vices, so they can withstand more force when gripping objects such as metal sheets or pipes.

They also have better durability because there are fewer moving parts compared to manual vices that rely on human strength or muscle power to operate them.

4. Can Be Used in Many Applications

The machine vice is one of the most versatile tools you can have in your workshop. It can be used to hold, clamp and secure many different items, including pieces of wood and metal.

The machine vice can also make drilling holes in materials more accessible and more precise. The possibilities are endless regarding what you can do with the machine vice.

5. Portable and Easy to Transport

It's easy to move around the workshop with a portable vice because it's lightweight and compact. This makes it simple to transport to different locations if necessary, such as taking it outside for some projects that are better suited for outdoor use.

With some vices, such as the Bessey KVP-31000 vice Kit, it's possible to use them indoors or out without having any problems with them being too heavy or bulky for one location or another.

Overall, vice is an essential tool for the severe machinist. If you have some money to burn and are willing to invest in one, you probably won't regret doing so later on down the road.

However, if you are a hobbyist or DIY'er and are shopping on a budget, a clamp may be more your speed.

No matter what vice you choose, we hope this guide has helped point you in the right direction!

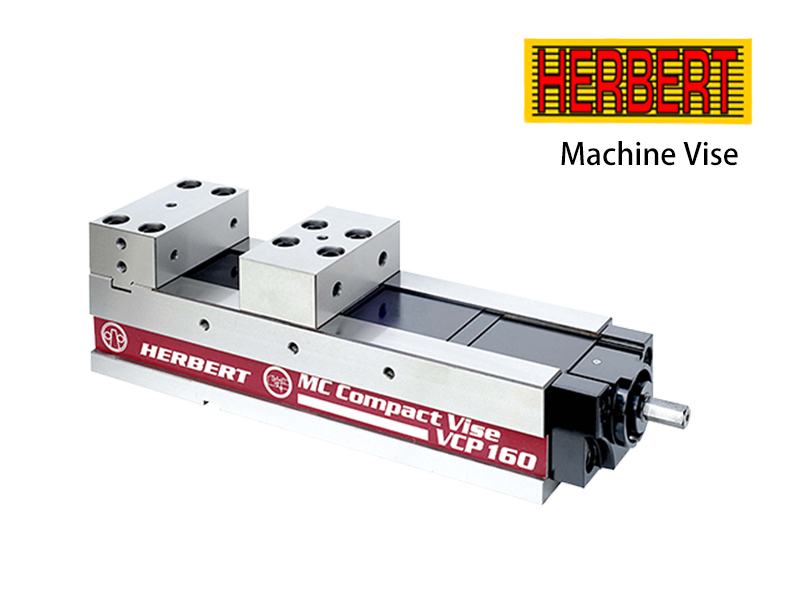

Contact HERBERT today for more informaiton!