What’s New

5 Reasons Why Quick Change Systems Are Revolutionizing Manufacturing

In today's fast-paced manufacturing world, efficiency and precision are essential to staying competitive. Quick Change Systems (QCS) are rapidly becoming a go-to solution for industries looking to optimize their production lines. Here are five reasons why:

1. Reduced Setup Time

Quick Change Systems (QCS) are designed to significantly cut down setup times, sometimes by as much as 90%. This is achieved by facilitating fast and seamless changeovers between tools and fixtures. Instead of manually repositioning or recalibrating machines, operators can quickly swap out components, leading to reduced idle machine time. The result is a marked improvement in machine utilization, allowing for higher production output in less time. For industries with frequent changes in production, this efficiency translates to substantial gains in overall productivity.

2. Improved Accuracy and Precision

QCS ensure consistent accuracy by utilizing standardized components such as base plates and zero-point clamping units. These elements maintain fixed, repeatable reference points, ensuring that every fixture or tool is positioned exactly where it needs to be—without manual adjustment. This repeatability is particularly vital for industries where precision is critical, such as aerospace, medical devices, and automotive manufacturing. By guaranteeing that every setup is accurate, QCS help to eliminate human error and ensure the highest quality standards in production.

3. Enhanced Flexibility

One of the standout features of QCS is their adaptability across a range of machine tools, including CNC milling machines, lathes, and vertical machining centers. QCS can accommodate various workpieces or tool configurations, allowing operators to transition quickly between different jobs or production batches. The ability to make these adjustments without the need for extensive recalibration enhances operational flexibility, especially in environments where production demands are constantly changing. This flexibility is key for manufacturers seeking to handle diverse product lines or custom orders with minimal downtime.

4. Reduced Labor Costs

By automating the process of changing tools and fixtures, QCS eliminate the need for manual labor during setup transitions. This reduction in manual intervention results in significant savings in labor costs, as fewer operators are required to manage the equipment. Instead, operators can focus on higher-value tasks, such as quality control, production monitoring, and system optimization. The overall improvement in workflow efficiency leads to enhanced productivity, allowing manufacturers to optimize resources and achieve more with fewer labor inputs.

5. Application Across Multiple Industries

Quick Change Systems (QCS) have proven to be valuable tools across a broad spectrum of industries, enhancing production efficiency and precision. Here are the key industries where QCS are making a significant impact:

Automotive Manufacturing

In the fast-paced world of automotive manufacturing, QCS enable rapid tool and fixture changes. Whether it's switching between different vehicle models or modifying the production line for new parts, QCS reduce downtime and streamline transitions. Automotive manufacturers benefit from higher throughput, as well as the flexibility to adapt to custom vehicle production demands. This system's precision also ensures that each component meets tight tolerance requirements, maintaining the high standards of quality expected in the industry.

Aerospace Industry

Aerospace manufacturers deal with extremely complex and critical components, where precision is non-negotiable. QCS play an essential role in maintaining this precision while allowing for the rapid changeovers needed to meet production demands. In aerospace, where the slightest deviation can compromise safety, QCS offer repeatable accuracy with every setup. The system's ability to adapt quickly ensures that production can continue without delays, even when transitioning between different parts of aircraft engines, fuselages, and other critical elements.

Electronics Manufacturing

In the consumer electronics sector, rapid product evolution is the norm. As designs frequently change, manufacturers need systems that can adapt quickly. QCS provide the ability to efficiently switch between different configurations and assembly setups, shortening product development cycles. The speed of changeovers is crucial here, as it allows manufacturers to keep up with tight market deadlines while maintaining precision in the assembly of small and delicate components, such as circuit boards and microchips.

Medical Device Manufacturing

Precision and reliability are paramount in the medical device industry. From surgical instruments to implants, the accuracy of every part must meet stringent health and safety standards. QCS enable manufacturers to achieve the necessary precision through repeatable and accurate setups, ensuring consistency in production. The system also allows for flexibility, supporting the frequent changes in production runs required by custom or prototype medical devices.

Metalworking and General Machining

For metalworking and machining shops that handle varied part designs and materials, QCS enhance the ability to move between different jobs with minimal downtime. Whether processing small batch runs or large production volumes, the system ensures fast and secure fixture changes while maintaining precision. This adaptability is particularly beneficial for workshops dealing with custom parts or frequently shifting production demands, allowing them to increase productivity without sacrificing quality.

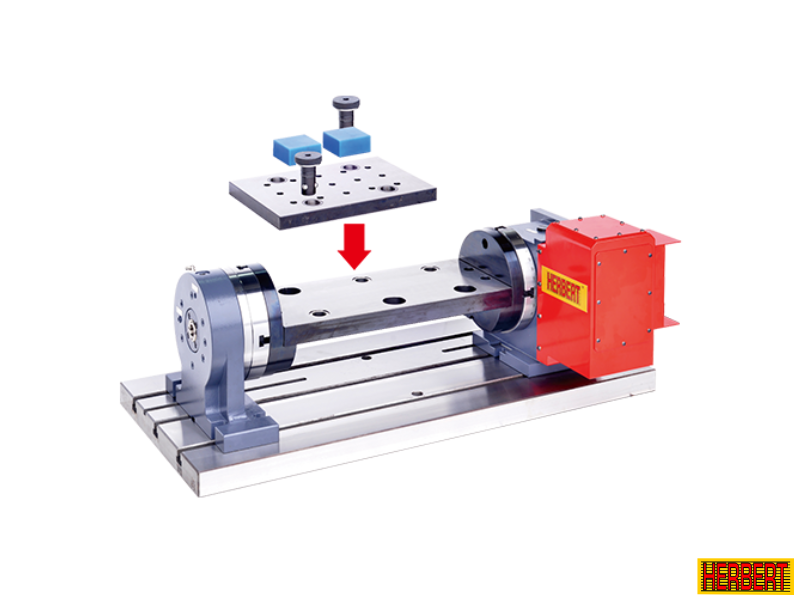

The Herbert Advantage

At Herbert Enterprise Co., Ltd., we specialize in providing cutting-edge Quick Change Systems that integrate seamlessly with your existing machinery. Our systems reduce downtime, improve accuracy, and offer scalable solutions for dynamic production environments.

Call to Action

To learn more about how Herbert's Quick Change Systems can transform your manufacturing operations, visit our website at www.her-bert.com or contact us to schedule a demo. Join us in revolutionizing your production line with speed and precision.