What’s New

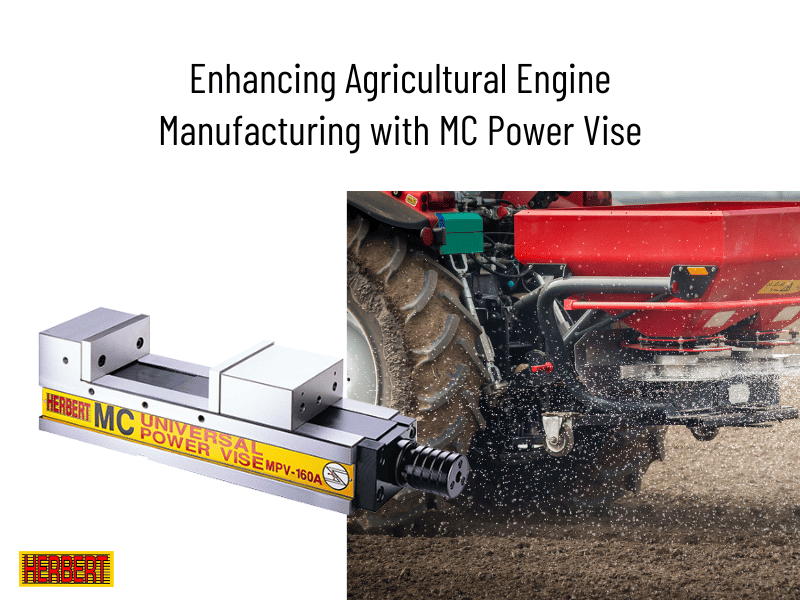

Enhancing Agricultural Engine Manufacturing with MC Power Vise

In the agricultural machinery industry, precision and efficiency are essential to producing durable and reliable engines that withstand demanding conditions. The MC Power Vise (MPV) plays a crucial role in optimizing the machining process of agricultural engines, ensuring stability, accuracy, and efficiency in manufacturing components such as cylinder heads, crankcases, and gear housings.

With its advanced design, high clamping force, and durability, the MC Power Vise is the ideal workholding solution for machining agricultural engine parts. This article explores how the MPV enhances the manufacturing process and ensures superior performance in agricultural engines.

________________________________________

Why Workholding Matters in Agricultural Engine Manufacturing

Agricultural engines power essential farming equipment such as tractors, harvesters, irrigation pumps, and tillers. These engines must be robust, wear-resistant, and built with precise tolerances to function reliably in extreme conditions, including dust, moisture, and heavy loads.

To ensure high-quality engine production, workpieces must be securely clamped during machining. Improper workholding can lead to vibration, misalignment, or workpiece movement, which affects accuracy and product lifespan. The MC Power Vise provides a stable and rigid clamping solution, ensuring precision, repeatability, and efficiency in the manufacturing of agricultural engine components.

________________________________________

Key Features of MC Power Vise and Their Benefits for Agricultural Engine Machining

1. High Strength and Bending Resistance for Heavy-Duty Machining

The MPV double-force vise body is engineered with a vertical rib structure, significantly enhancing bending resistance. This feature is critical in machining agricultural engine parts, which often involve heavy cutting forces and deep milling operations.

• Why It Matters for Agricultural Engines:

o Ensures rigid clamping for large engine components such as cylinder blocks and crankcases.

o Prevents deformation during high-speed milling and drilling processes.

________________________________________

2. Superior Clamping Force for Secure Workholding

The oil-free clamping mechanism, combined with a slope design, generates over 13 times the clamping force. This high force ensures that workpieces remain securely in place throughout the machining process.

• Why It Matters for Agricultural Engines:

o Eliminates workpiece slippage, ensuring high precision in machining engine blocks and transmission housings.

o Provides consistent and repeatable clamping, reducing the risk of errors in high-volume production.

________________________________________

3. Floating Prevention Mechanism for Improved Accuracy

A hidden floating prevention mechanism minimizes workpiece movement during clamping, significantly reducing floating rates. This ensures stable positioning and prevents any misalignment.

• Why It Matters for Agricultural Engines:

o Essential for machining precision engine parts like camshafts, pistons, and connecting rods.

o Ensures accurate alignment for multi-axis machining, improving consistency in engine assembly.

________________________________________

4. Omnidirectional Chip Prevention for Clean Operations

The MPV features a movable design structure within a recessed groove, providing comprehensive chip prevention. This feature helps prevent chips from accumulating in critical moving parts.

• Why It Matters for Agricultural Engines:

o Avoids contamination and blockage when machining engine cylinder heads and fuel injection components.

o Ensures smooth operation even in high-speed milling applications, reducing maintenance time.

________________________________________

5. Heat-Treated Surfaces for Enhanced Durability

Both the working surface and sliding surface of the MPV undergo heat treatment, achieving hardness levels above HRC 45. This improves wear resistance and extends the vise's service life.

• Why It Matters for Agricultural Engines:

o Withstands the high pressure and continuous use required in automated machining lines.

o Ensures long-term reliability, reducing the need for frequent replacements or recalibrations.

________________________________________

6. Dust-Proof Cover for Reliable Performance in Harsh Environments

The dust-proof cover effectively prevents cutting chips, debris, and dust from entering the vise mechanism. This feature is especially beneficial in dirty and abrasive machining environments, such as those found in agricultural equipment manufacturing.

• Why It Matters for Agricultural Engines:

o Keeps the vise clean and operational, reducing downtime for maintenance.

o Prevents iron chip buildup, which can lead to clamping malfunctions or inaccurate positioning.

________________________________________

MC Power Vise Applications in Agricultural Engine Manufacturing

The MC Power Vise is widely used in the production of various engine components for agricultural machinery, including:

✔️ Cylinder Heads & Blocks – Ensures precise milling and drilling of mounting points.

✔️ Crankcases & Gear Housings – Provides stable clamping for deep pocket machining.

✔️ Camshafts & Flywheels – Prevents misalignment in multi-axis machining.

✔️ Transmission Housings – Enhances accuracy in complex shape cutting.

By integrating the MC Power Vise into agricultural engine production lines, manufacturers reduce cycle times, improve accuracy, and enhance the durability of machined components.

________________________________________

Why Choose Herbert's MC Power Vise?

At Herbert Enterprise Co., Ltd., we understand the challenges faced by agricultural engine manufacturers. Our MC Power Vise is engineered to provide superior stability, high precision, and long-lasting durability, making it the perfect solution for machining critical engine components.

✔️ Enhanced rigidity for high-torque applications

✔️ High clamping force for secure and stable machining

✔️ Chip-resistant design for cleaner, more efficient operations

✔️ Long lifespan and wear resistance for continuous use

________________________________________

Conclusion

Manufacturing agricultural engines requires precision, strength, and durability to ensure optimal performance in demanding environments. The MC Power Vise provides a high-performance clamping solution that enhances machining accuracy, efficiency, and workpiece stability.

By choosing Herbert's MC Power Vise, manufacturers can improve production efficiency, reduce defects, and ensure the long-term reliability of agricultural engine components.

For more information on how our MC Power Vise can optimize your machining operations, visit our website or contact our team today!