What’s New

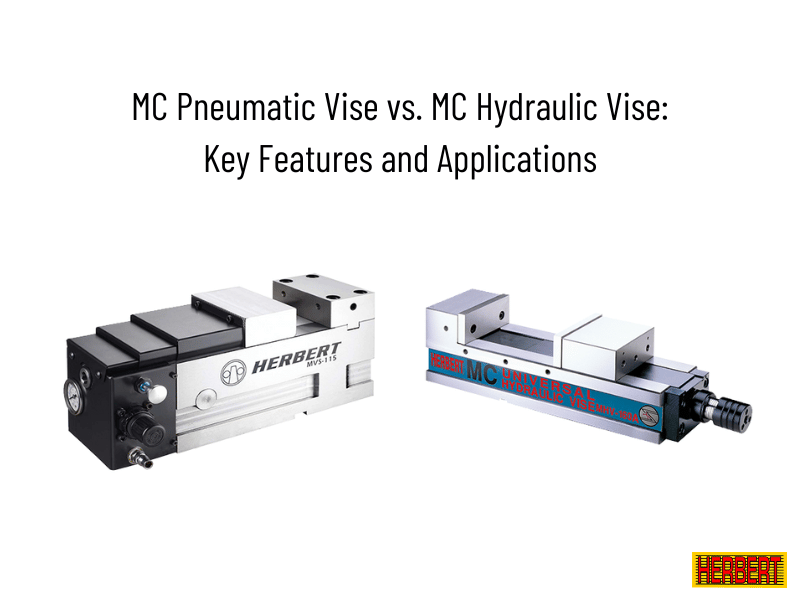

MC Pneumatic Vise vs. MC Hydraulic Vise: Key Features and Applications

In the world of precision machining, workholding tools like vises play a critical role in ensuring efficiency, accuracy, and stability during operations. Two of the most commonly used vises are the MC Pneumatic Vise and the MC Hydraulic Vise, each offering unique advantages suited to specific machining needs. Understanding their features, benefits, and applications can help manufacturers make informed decisions to optimize their processes.

________________________________________

What is an MC Pneumatic Vise?

An MC Pneumatic Vise operates using compressed air to generate clamping force. These vises are designed for rapid and automated clamping, making them ideal for high-speed and repetitive machining tasks.

Key Features of MC Pneumatic Vise:

• Quick Clamping: Uses compressed air to achieve fast clamping and unclamping, reducing setup times.

• Automation Friendly: Can easily integrate into automated systems for batch processing or robotic operations.

• Light to Medium Clamping Force: Suitable for materials that do not require extremely high clamping pressure.

• Low Maintenance: Fewer moving parts compared to hydraulic systems, leading to reduced maintenance needs.

• Eco-Friendly: Requires no hydraulic oil, making it a cleaner option for environments concerned with oil leakage or contamination.

Applications of MC Pneumatic Vise:

• CNC Milling: Ideal for light-to-medium duty machining tasks.

• Electronics Manufacturing: Perfect for handling delicate or smaller components.

• Batch Processing: Suitable for repetitive operations requiring frequent clamping and unclamping.

• Assembly Lines: Used in automated assembly processes where speed and consistency are key.

________________________________________

What is an MC Hydraulic Vise?

An MC Hydraulic Vise utilizes hydraulic fluid to generate powerful and precise clamping force. These vises are known for their high clamping pressure and stability, making them suitable for demanding machining tasks.

Key Features of MC Hydraulic Vise:

- High Clamping Force: Offers significantly higher clamping pressure, ensuring workpieces are held securely during heavy-duty operations.

- Precision Control: Provides precise and repeatable clamping, critical for applications requiring tight tolerances.

- Durability: Designed to withstand high pressures and forces, making it highly reliable for long-term use.

- Wide Compatibility: Suitable for handling larger or heavier workpieces.

- Advanced Sealing: Prevents hydraulic fluid leaks, ensuring a clean and safe workspace.

Applications of MC Hydraulic Vise:

- Heavy-Duty Machining: Perfect for milling, drilling, and grinding operations on tough materials like steel and alloys.

- Aerospace and Automotive Manufacturing: Used in precision machining of critical components with strict quality standards.

- Tool and Die Making: Ensures stability for intricate machining of dies and molds.

- High-Volume Production: Handles large-scale manufacturing processes with consistent performance.

________________________________________

| Feature | MC Pneumatic Vise | MC Hydraulic Vise |

|---|---|---|

| Clamping Force | Light to medium | High |

| Speed | Faster clamping and unclamping | Moderate, but offers precision control |

| Maintenance | Low maintenance | Requires more maintenance due to hydraulic components |

| Cost | Generally more cost-effective | Higher initial investment |

| Applications | Light-duty, repetitive tasks | Heavy-duty, high-precision machining |

| Environmental Impact | No oil required, eco-friendly | Requires hydraulic oil |

________________________________________

How to Choose Between Pneumatic and Hydraulic Vises

When selecting the right vise for your needs, consider the following factors:

1. Clamping Force Requirements:

- For heavy-duty machining or tough materials, a hydraulic vise is the better choice.

- For lighter materials or high-speed clamping, go for a pneumatic vise.

2. Automation Needs:

- If your operation involves automation or robotic systems, the pneumatic vise integrates seamlessly due to its faster cycle times.

3. Material Handling:

- For delicate or small components, use a pneumatic vise to avoid over-clamping.

- For larger, heavier workpieces, a hydraulic vise offers the required stability and force.

4. Budget and Maintenance:

- Pneumatic vises are more cost-effective upfront and require less maintenance.

- Hydraulic vises have a higher initial cost but are more durable and suited for demanding operations.

________________________________________

Conclusion

Both MC Pneumatic Vise and MC Hydraulic Vise serve essential roles in modern machining. While pneumatic vises excel in speed and automation for lighter tasks, hydraulic vises dominate in heavy-duty applications requiring high clamping force and precision.

At Herbert Enterprise Co., Ltd., we offer a wide range of high-quality pneumatic and hydraulic vises tailored to meet diverse machining needs. Whether you prioritize speed, precision, or durability, we have the right solution for your production line. To learn more, visit our website or contact us for personalized advice. Let us help you elevate your machining operations with the perfect workholding solution.